NNHS Robotics uses 3D printing to support local hospitals

Photo by Geoffrey Schmit

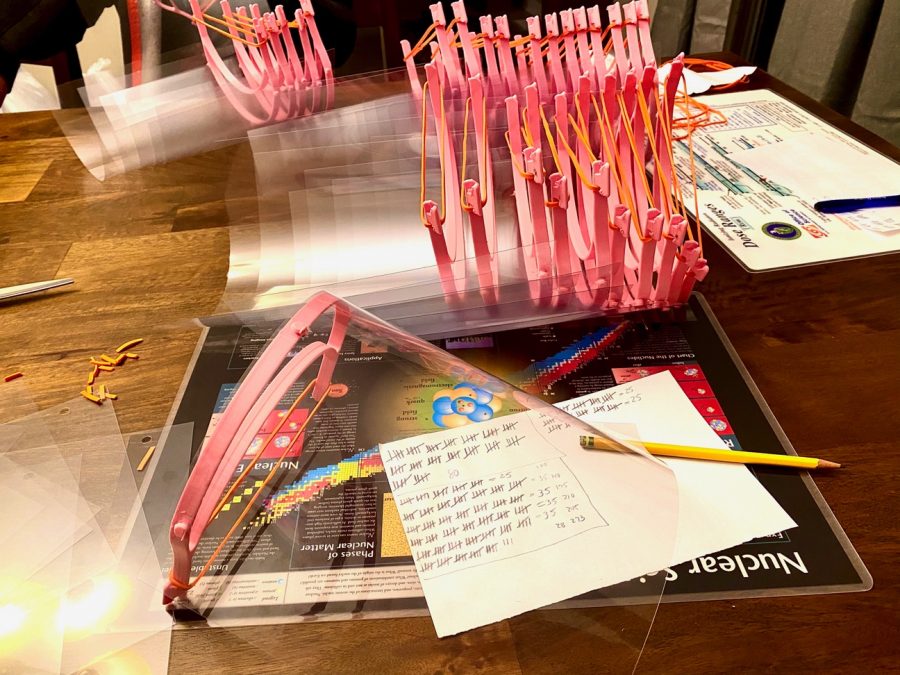

Every day of quarantine, Naperville North junior Maria Patni hears the whirring of her 3D printer in her house. Using skills she has learned as a member of the Huskie Robotics team, Maria, along with six other team members, uses a 3D printer to construct face shields to donate to local hospitals, supporting the fight against COVID-19 in collaboration with the NNHS Career and Technical Education department’s Mr. Schmit.

“It doesn’t take that much time to keep the printer running and assemble the masks, but it has a big impact in the medical world, so I decided that I wanted to take part in this effort,” Patni said.

The United States has an overall shortage of personal protective equipment (PPE) for hospitals to use in defense against COVID-19. As COVID-19 cases in the U.S. continue to increase, healthcare workers have expressed a growing need for supplies such as face shields, surgical masks and gowns. According to a survey conducted by GetUsPPE.org, 36% out of the 978 responding institutions no longer have a supply of face shields, while 55% will require them in at least a week. As a member of a volunteer organization designed to address the PPE limitations in Illinois, the western suburbs node of Illinois PPE, Schmit shared the project with members of Huskie Robotics.

“Hospitals and medical professionals are very appreciative of this response for PPE. There are medical professionals who need PPE but don’t have the support of their employer. We get PPE to them as well but don’t advertise it to protect them,” Schmit said.

Schmit heard about the 3D printer company “Prusa,” a provider of face shields for medical professionals in the Czech Republic, and decided to find a 3D printer design that he could use to print his own face shields as efficiently as possible. The face shields follow a design known as the “Swedish Shield,” which was created by Richard Beien, one of the founders of a Swedish group that was initially providing face masks for the Swedish Covenant Hospital in Chicago.

“Jacob Kaplan, a sophomore at NNHS and member of Huskie Robotics, remixed the design such that we could print stacks of frames,” Schmit said.

The face shield consists of three components: a 3D-printed frame, a clear plastic presentation cover and an elastic band. Schmit as well as the robotics team members are self-funding the materials for the shields.

“I’ve been printing the frames, ordering buttonhole elastic from Walmart for the straps and [buying] foam tape from Amazon. For the actual shield part, I’ve been ordering plastic covers that are used for lamination from Amazon,” Patni said.

Once the frames are printed, the whole shield has to be assembled before they can be delivered to hospitals. Schmit’s family works together to get this done.

“There are a few steps, and we set up an assembly line on the dining room table. Five of us assembled over 250 shields in less than two hours,” said Schmit.

The next step in the process is the delivery of the shields to nearby hospitals that are in need of PPE. Depending on the institution, Schmit and the students will either deliver the PPE to the locations and their workers, or couriers will be sent by the organizations to pick up the equipment.

“My mom, Mr. Schmit and I collaborate to figure out which hospitals or nursing homes need supplies,” Patni said.

The PPE is sent to various locations in the suburban area, including Edward’s Hospital, Amita Health in Joliet and Symphony Care Nursing Home.

“We have delivered almost 1,000 face shields to the organizations,” Schmit said. “We have also delivered 3D-printed parts for over 100 face masks and over 300 bands that relieve the stress of surgical mask elastic.”

Huskie Robotics is making an impact outside of Illinois as well. Alex Spitzner, an NNHS sophomore, is self-isolating and printing shields in Traverse City, Michigan.

“I want to help my community in any way I can, so I am helping to print face shields and ear straps for local hospitals in the Traverse City area,” Spitzner said. “I started making them [on] April 1 and have been printing since then.”

Meanwhile, Schmit and the students continue to work with Illinois PPE to distribute supplies to local hospitals and contribute to the COVID-19 relief effort.

“Until hospitals decide they don’t need any more, I’ll continue to make [PPE],” Patni said.

Reyah is a senior at North and is excited to take on the role of Editor-in-Chief in her third year writing for The North Star. This year, she hopes to...

Zea is a senior at North and can’t wait to spend her third year at The North Star as its Special Projects Editor. She’s looking forward to making her...